Air Casters are the Perfect Choice for Moving Heavy Loads

We are the premier manufacturer of safe load moving solutions that utilize plant air to provide nearly frictionless movement with omni-directional travel, therefore eliminating forklifts, overhead cranes, dollies, and other bulky material handling equipment.

|

Fast, precise, flexible product transfer Move 5,000 lb with 10 lb push Low-profile ergonomic solution |

Eliminate forklifts, overhead cranes, etc. 360° omni-directional movement Simply turn on the air to move |

|

Air Casters, often referred to as Air Bearings, float heavy loads on a lubricated thin-film cushion of air reducing the coefficient of friction, requiring only 2 to 3 pounds of pushing force per 1000 pounds of load.

Air Casters enable smaller work cells to conserve factory resources, resulting in increased productivity. Large heavy loads can effortlessly be moved through production and assembly lines.

|

|

Air Caster Systems for Production Environments

|

Air Planks consist of two or more Air Caster elements mounted to a common extrusion piece customized to each user application. Typically used in groups of two or more for loads with consistent width but varying lengths.

Planks can be permanently mounted or placed beneath the product at the beginning of a production line. Common industry use includes electrical switch gear, control cabinets, small modular structures, pallet mounted equipment, and production fixtures.

|

|

A derivation of standard planks where one end, joined with a cross-beam, creating a U-shaped structure, functions as a high capacity pallet jack. Cross-beam Air Planks are typically used to move smaller footprint electrical enclosures or cabinets.

|

|

Air Pallets are single platforms, constructed of steel or aluminum, allowing direct product placement on the top deck surface for transfer. Typical industry use includes manufacturers of transformers, paper roll handling, air compressors, heavy equipment, axle assembly, and various other products. Air Pallets are affordably customized with features and options to exceed performance expectations.

|

|

Air Caster Load Modules are used in quantities of three or more for products with large variations in length and width. Options allow direct bolting to equipment replacing existing wheels and rollers or placed beneath the load when movement is desired.

They are available with different manifold configurations for ease of use and optimized for different types air distribution depending on offset loading conditions.

Typically used as permanent installs to existing equipment where periodic movement is desired for routine maintenance. Excellent choice for modular structures and fixtures to allow heavy load transfer through assembly.

|

|

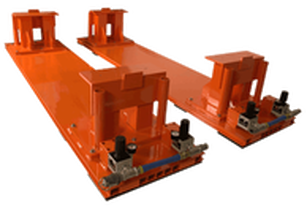

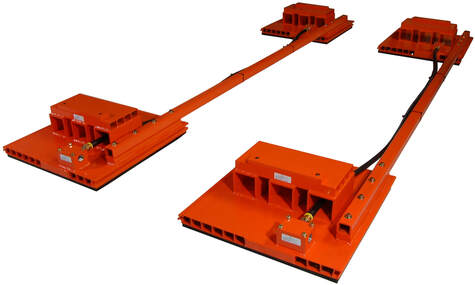

Cross-beam Air Caster Load Modules are standard modules connected with a common cross beam establishing a fixed width center to center spacing of the Load Modules. A cross over hose simplifies the air connections.

The cross-beam provides stability to prevent caster tipping when long and narrow contact points exists such as tubing, I-beams or headers.

Adjustable slotted beams are available for 1-inch increment adjustment for varying widths. Commonly used in modular housing and modular structures manufacturing.

|

Discover the benefits of advanced Air Caster Technology

High quality, cost-effective load moving solutions

Air Casters for Machinery & Equipment Moving

|

Air Caster Rigging Systems, also referred to as Air Bearing Modules, are the most versatile Air Caster systems. Rigging Systems are primarily used for machinery and equipment moving where load sizes, length, width, and height distribution vary dramatically.

|

Frequently Asked Questions

What is the minimum number of Air Casters to move a load?

3 Air Casters is the minimum required, with the casters arranged in a triangular pattern.

How much pushing force is required to move a load on Air Casters?

On a smooth sealed concrete floor, the coefficient of friction is approximately .002 to .003, requiring 2 to 3 pounds of pushing force for each 1000 pounds of load on a flat level floor.

Is there a minimum load allowed on a specific Air Caster size?

Yes, each caster has a minimum load rating between 5- 10% of its maximum capacity. In many cases the regulation is the issue trying to operate at low pressure ranges down to 2 to 3 psi. Often this can be circumvented by ganging several Air Casters on a single regulator to provide higher adjustment ranges for equally loaded casters.

Will my floors work for Air Casters?

This is the single most important question presented by most end users. Air Casters require smooth machine trialed finished concrete with a high-quality sealer to ensure the concrete is not porous. Painted and epoxy coated floors work exceptionally well. Air Casters will protect your floor finish over conventional rollers and wheels.

Ready to get started with Air Casters?

Call us: (800) 323-0571, email us: [email protected], or click the button below