Air Skates provide nearly frictionless movement of heavy machinery & equipmentMajor companies throughout the world use and depend upon innoAIRvation machinery moving Air Caster Rigging Systems for moving heavy loads on a thin film of compressed air utilizing air film technology.

Often referred to as Air Skates, Air Dollies, Air Bearing Modules, or Machine Skates, loads can be moved easily, safely and affordably eliminating floor damage typical with wheels or machinery rollers.

An exceptional choice to move vibration sensitive equipment, machine tools, stamping presses, injection mold machines, and large fabricated structures, offering a low frictional force of only 1 to 2 pounds of pushing force per 1,000 pounds of load.

|

Omni-directional movements provide superior control in tight areasBesides their nearly frictionless properties, Air Skates have omni-directional (four directional) travel making 90 degree turns easy to negotiate, and final positioning a simple task in tight congested areas.

Often, machine tools and production equipment, to conserve valuable floor space, are positioned closely together requiring difficult rigging maneuvers for installation or removal.

Typically, the first or last few feet of movement are the most difficult and time consuming. This task can be made easy by using Rigging Systems.

|

|

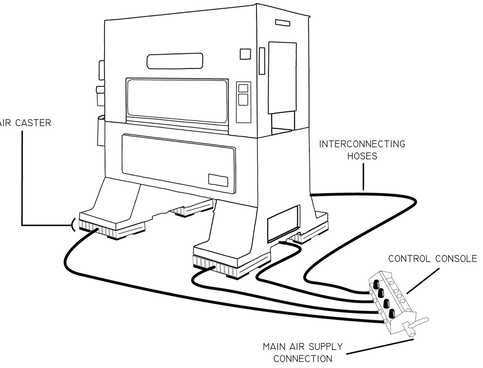

Versatile Air Skates are simple to operate & affordableAir Caster Rigging Systems consist of 4 or 6 lightweight aluminum extrusion load modules, one precision control console for independent regulation compensating for offset loading, and 4 or 6 color-coordinated interconnect hoses.

Having no internal moving parts, Rigging Systems offer a reliable, versatile, cost-effective solution to move heavy loads with large variations in length, width and height.

Simply place the modules beneath the load, connect the interconnect hoses, then adjust the pressure to each module based on point loading, then effortlessly move your load.

Make moves in minutes, on short notice, with an affordable Rigging System often justified in just one weekend of machinery or equipment moves.

| |||||||

Discover the benefits of advanced Air Caster Technology

High quality, cost-effective load moving solutions

Air Caster Rigging System Specifications

-

4 Module System

-

6 Module System

-

Single Module

<

>

| Model No. | Module Quantity | System Capacity (lbs) | Length (in) | Width (in) | Height (in) |

|---|---|---|---|---|---|

| 4LD12GHD | 4 | 8,000 | 12 | 12 | 2.25 |

| 4LD15GHD | 4 | 14,000 | 15 | 15 | 2.3 |

| 4LD18GHD | 4 | 20,000 | 18 | 18 | 2.3 |

| 4LD21GHD | 4 | 32,000 | 21 | 21 | 2.3 |

| 4LD24GHD | 4 | 40,000 | 24 | 24.7 | 2.5 |

| Model No. | Module Quantity | System Capacity (lbs) | Length (in) | Width (in) | Height (in.) |

|---|---|---|---|---|---|

| 6LD12GHD | 6 | 12,000 | 12 | 12 | 2.25 |

| 6LD15GHD | 6 | 21,000 | 15 | 15 | 2.3 |

| 6LD18GHD | 6 | 30,000 | 18 | 18 | 2.3 |

| 6LD21GHD | 6 | 48,000 | 21 | 21 | 2.3 |

| 6LD24GHD | 6 | 60,000 | 24 | 24.7 | 2.5 |

| Model No. | Capacity (lbs) | Length (in) | Width (in) | Height (in.) |

|---|---|---|---|---|

| LD12GHD | 2,000 | 12.2 | 12.2 | 2.38 |

| LD15GHD | 3,500 | 15.2 | 15.2 | 2.38 |

| LD18GHD | 5,000 | 18.2 | 18.2 | 2.38 |

| LD21GHD | 8,000 | 21.2 | 21.2 | 2.38 |

| LD24GHD | 10,000 | 24.2 | 24.8 | 2.5 |

Advanced LD series Load Module for Equipment Moving

|

Precision Control ConsoleControl console includes 4 or 6 high-flow precision regulators with gauges, an on/off ball valve, and a system pressure gage to precisely control regulation to each module independently for optimum control compensating for offset load conditions.

|

Frequently Asked Questions

What is the minimum number of Air Casters to move a load?

3 Air Casters is the minimum required, with the casters arranged in a triangular pattern.

How much pushing force is required to move a load on Air Skates?

On a smooth sealed concrete floor, the coefficient of friction is approximately .002 to .003, requiring 2 to 3 pounds of pushing force for each 1000 pounds of load on a flat level floor.

Is there a minimum load allowed on a specific Air Caster size?

Yes, each caster has a minimum load rating between 5- 10% of its maximum capacity. In many cases the regulation is the issue trying to operate at low pressure ranges down to 2 to 3 psi. Often this can be circumvented by ganging several air casters on a single regulator to provide higher adjustment ranges for equally loaded casters.

Will my floors work for Air Skates?

This is the single most important question presented by most end users. Air Skates require smooth machine trialed finished concrete with a high-quality sealer to ensure the concrete is not porous. Painted and epoxy coated floors work exceptionally well. Air Skates will protect your floor finish over conventional rollers and wheels.

Request a FREE no-obligation quote

Call us, email us, or fill out the form below

|

Toll-free: (800) 323-0571

|

Local: (706) 323-0500

|

Email: [email protected]

|