How do Air Casters (Air Bearings) work?

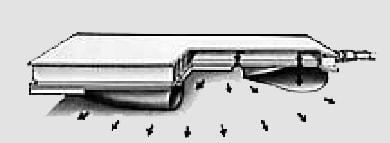

Step 1: Compressed air enters the load module chamber and fills the flexible torus bag and center chamber. At this point the Air Caster (Air Bearing) will inflate and seal off against the floor.

Step 2: As the pressure is increased, a state of equilibrium is achieved where the force up equals the force down. Note the downward force is the load or equipment to be moved, and the upward force is the internal air pressure times the effective torus bag area.

Step 3: Next the compressed air will take the path of least resistance which is underneath the torus bag. This film of air created is 3 to 5 thousandths thick and flows uniformly between the torus bag and the seal floor surface around the entire circumference.

Step 2: As the pressure is increased, a state of equilibrium is achieved where the force up equals the force down. Note the downward force is the load or equipment to be moved, and the upward force is the internal air pressure times the effective torus bag area.

Step 3: Next the compressed air will take the path of least resistance which is underneath the torus bag. This film of air created is 3 to 5 thousandths thick and flows uniformly between the torus bag and the seal floor surface around the entire circumference.

What are some advantages of using Air Casters?

Air Casters are generally used in lieu of wheels and have many advantages. All that is needed is a source of compressed air, a smooth sealed surface such as concrete, epoxy coated, or steel floor, and a load ranging in weight from 500 pounds to 40 tons. Some of the technical features that make Air Casters the preferred choice for moving heavy, bulky or sensitive loads are as follows:

|

|

What is the minimum number of Air Casters to move a load?

3 Air Casters is the minimum required, with the casters arranged in a triangular pattern.

How much pushing force is required to move a load on Air Casters?

On a smooth sealed concrete floor, the coefficient of friction is approximately .002 to .003, requiring 2 to 3 pounds of pushing force for each 1000 pounds of load on a flat level floor.

Is there a minimum load allowed on a specific Air Caster size?

Yes, each caster has a minimum load rating between 5- 10% of its maximum capacity. In many cases the regulation is the issue trying to operate at low pressure ranges down to 2 to 3 psi. Often this can be circumvented by ganging several air casters on a single regulator to provide higher adjustment ranges for equally loaded casters.

Will our floors work for Air Casters?

This is the single most important question presented by most end users. Air Casters require smooth machine trialed finished concrete with a high-quality sealer to ensure the concrete is not porous. Painted and epoxy coated floors work exceptionally well. Air Casters will protect your floor finish over conventional rollers and wheels.

Will Air Casters travel over expansion joints?

Expansion joints must be filled with an elastic filler material, such as epoxy based Devcon Flexane 94, to maintain expansion properties. For temporary moves, sheet metal overlays (20 gage or thinner) can be used to bridge the gap, allowing Air Casters to move over the joint. The leading edge must be taped with high-quality, 3-inch tape. Sheet metal should be wider than caster size. For an 18- or 21-inch caster, we recommend a 24-inch material.

What if our floor does not support Air Caster operation? Is there anything we can do?

Similar to crossing over expansion joints, sheet metal runways can be laid down to create a travel path for the casters. The sheet metal should be overlapped by 6 inches at each joint and taped.

Will Air Casters operate on an incline?

Yes, with caution. A component of the weight will increase the force to move or restrain the load from moving by itself. Extreme care must be taken to provide the necessary restraining force or pushing force. Tuggers or forklifts are tethered to loads in this circumstance.

Will Air Casters operate on exterior concrete?

No, exterior concrete is broom finished for antiskid properties and unsealed due to environmental exposure. This will not allow the casters to operate properly. Overlays are required on exterior concrete.

What size air compressor is required to operate an Air Caster system?

Air flow requirements vary per caster size, load capacity, and floor conditions. The air requirements depending on load capacity range from 20 to 140 SCFM per system. The average three phase air compressor has an output of 4 SCFM per horsepower, therefore a 5 HP to 35HP air compressor is required. In certain instances when the compressor has a larger air receiver, the short term demand can be accomplished for a given length of time, enabling a move before the tanks is drained and requires recharging.

Ready to get started with Air Casters?

Call us: (800) 323-0571, email us: [email protected], or click the button below